Plastic Injection Molding is one of the most widely used manufacturing processes in the modern world. From consumer electronics and medical devices to automotive components and everyday household products, plastic injection molding plays a critical role in large-scale plastic production.

Injection molding has remained dominant for decades not because it is new or trendy, but because it is reliable, scalable, and extremely efficient once production reaches volume. Understanding how it works—and when it makes sense to use it—can help companies make smarter decisions as products move from concept to large-scale manufacturing.

How Plastic Injection Molding Works in Manufacturing

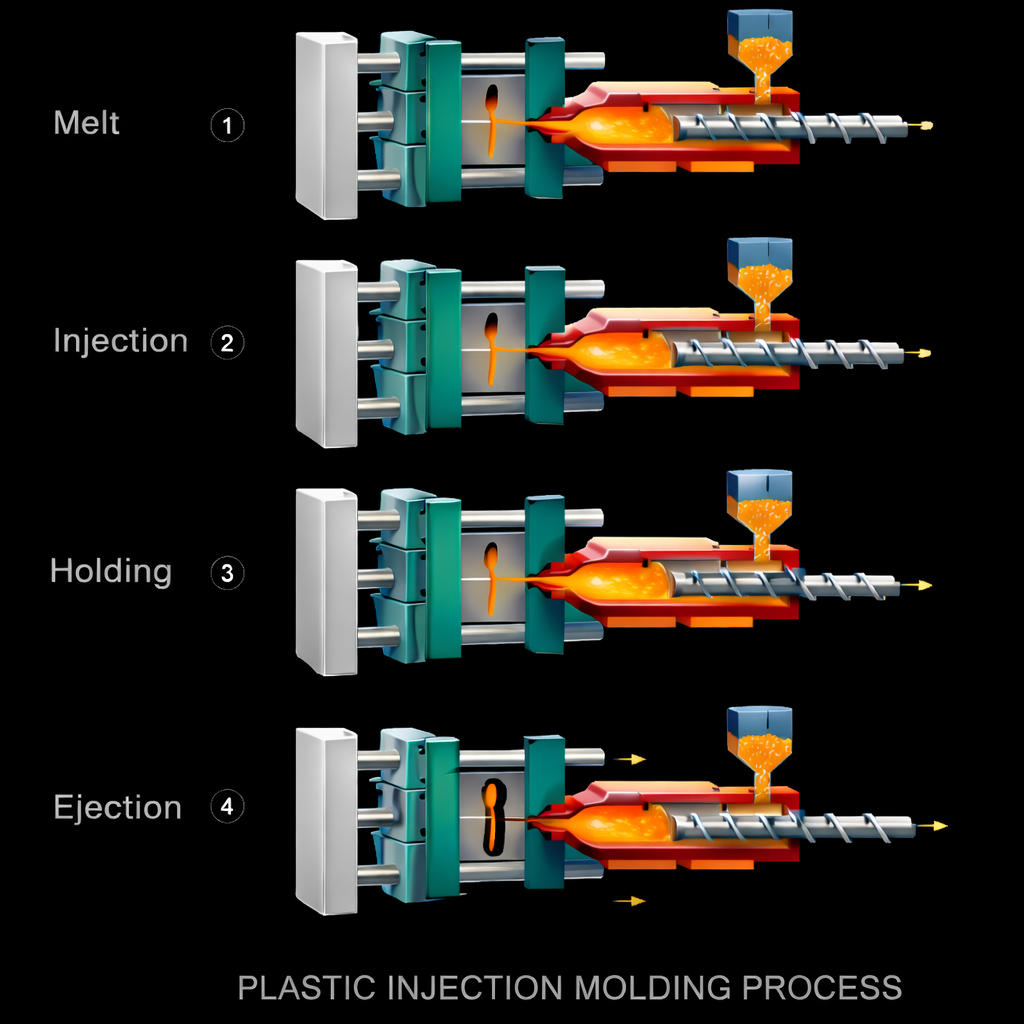

As shown in the 3D diagram below, the plastic injection molding process consists of four main stages

At its core,plastic injection molding is a process that turns plastic pellets into solid parts by using heat, pressure, and a precisely engineered mold. The plastic material is first fed into an injection molding machine, where it is heated until it becomes molten and flowable. A rotating screw then pushes the molten plastic forward and injects it into a closed mold under high pressure.

The mold itself is typically made from steel or aluminum and contains a cavity that defines the final shape of the part. Once the molten plastic fills this cavity, it begins to cool and solidify. After cooling, the mold opens and the finished part is ejected. The mold then closes again, ready to repeat the same cycle.

This entire process can take anywhere from a few seconds to under a minute, depending on the part size, wall thickness, and material. Because the cycle is fast and highly repeatable, injection molding is ideal for producing large quantities of identical parts with consistent quality.

Why Plastic Injection Molding Is Used for Mass Production

Injection molding truly shines when production volumes increase. Once a mold is built and dialed in, the cost per part drops dramatically as more units are produced. This is why injection molding is the standard choice for products that need to be manufactured in the thousands or millions.

Another key advantage is consistency. Every part produced from the same mold is nearly identical in shape, size, and surface finish. This level of repeatability is especially important for products that require precise assembly or tight tolerances. Even small variations between parts can cause problems during assembly or reduce product reliability, and injection molding minimizes that risk.

In addition, injection molding allows for complex geometries to be produced in a single operation. Features such as thin walls, snap-fits, ribs, and internal structures can often be molded directly into the part, eliminating the need for secondary machining or assembly.

Real-World Example: Consumer Electronics

Consumer electronics offer one of the clearest examples of injection molding at work. Inside a smartphone, there are numerous plastic components used to support internal parts, protect sensitive electronics, and ensure proper alignment during assembly. These components must be lightweight, strong, and produced with extremely tight tolerances.

For large electronics manufacturers, injection molding is the only practical way to meet these requirements at scale. Once the product design is finalized, molds are created to produce thousands of identical parts per day. This ensures that every phone assembled on the production line fits together smoothly, with minimal variation between units.

Real-World Applications: From Automotive to Medical and Everyday Products

Plastic injection molding plays a critical role across industries where reliability, consistency, and scale matter. While the end products may look very different, the underlying manufacturing logic is often the same.

In the automotive industry, injection molding is used to produce a wide range of components, from visible interior panels to hidden functional parts such as clips, brackets, vents, and housings. A single vehicle can contain hundreds of injection-molded plastic parts, many of which must perform under constant vibration, temperature fluctuations, and long-term mechanical stress. To meet these demands, manufacturers often rely on engineering plastics like glass-filled nylon or reinforced polypropylene. Injection molding allows these materials to be formed into complex geometries while maintaining tight tolerances, making large-scale vehicle assembly both efficient and repeatable.

The same principles apply in the medical field, where injection molding is used to manufacture components that require extremely high consistency and dimensional accuracy. Products such as syringe housings, diagnostic device enclosures, and disposable medical components are often produced in large volumes under controlled conditions. In these applications, even small variations between parts can lead to performance issues or safety concerns. Injection molding provides the level of process control needed to ensure that every unit meets strict regulatory and functional requirements.

Everyday consumer products also rely heavily on injection molding, even when the parts appear simple. Take plastic bottle caps as an example. Despite their straightforward appearance, they require precise threading, reliable sealing performance, and consistent material behavior. Injection molding makes it possible to produce millions of identical caps with uniform quality, ensuring they function the same way every time a consumer uses them.

Across automotive, medical, and consumer applications, injection molding serves the same fundamental purpose: enabling complex plastic parts to be produced at scale with predictable quality. While the materials and performance requirements may vary, the process remains a cornerstone of modern manufacturing wherever consistency and volume are essential.

Limitations and Design Considerations

Despite its advantages, injection molding is not the right solution for every stage of product development. The most significant limitation is the upfront cost of tooling. Designing and manufacturing a mold requires time and investment, which can be difficult to justify when a product design is still evolving.

Once a mold is built, making design changes can be expensive or even impractical. For this reason, injection molding is best suited for products with stable designs and clearly defined production volumes. Attempting to use injection molding too early in the development process can slow down iteration and increase overall risk.

How Plastic Injection Molding and 3D Printing Work Together

In modern manufacturing, injection molding and 3D printing are often used together rather than as competing technologies. 3D printing is commonly used in the early stages of product development, where speed and flexibility matter more than unit cost. Designers can quickly produce prototypes, test form and fit, and refine designs without committing to expensive tooling.

Once the design is validated and demand increases, injection molding becomes the logical next step. At this stage, the product geometry is stable, and the focus shifts toward cost efficiency, consistency, and scalability. The transition from 3D printing to injection molding allows companies to move smoothly from prototyping to mass production without unnecessary risk.

This hybrid approach is increasingly common among startups and established manufacturers alike. It combines the agility of additive manufacturing with the efficiency of traditional mass production, allowing products to scale at the right time.

When Injection Molding Makes Sense

Injection molding is most effective when production volumes are high, designs are finalized, and long-term cost control is a priority. It is not a rapid-iteration tool but rather a production powerhouse built for consistency and scale.

Companies that understand this distinction can plan their manufacturing strategy more effectively, choosing flexible methods early on and transitioning to injection molding once the product is ready for market.

Plastic injection molding is a cornerstone of modern manufacturing. By combining precise tooling, controlled processing, and high repeatability, it enables the efficient production of plastic parts at massive scale. While it requires careful planning and upfront investment, its benefits in consistency, quality, and unit cost make it indispensable across industries.

When used at the right stage of product development—and often alongside 3D printing—plastic injection molding becomes a powerful tool for turning validated designs into reliable, scalable products.