3D Printing Services

From Prototype to Production

Industrial-grade FDM, SLA, SLM, & SLS. Strict tolerances, fast turnaround.

Get Instant Quote

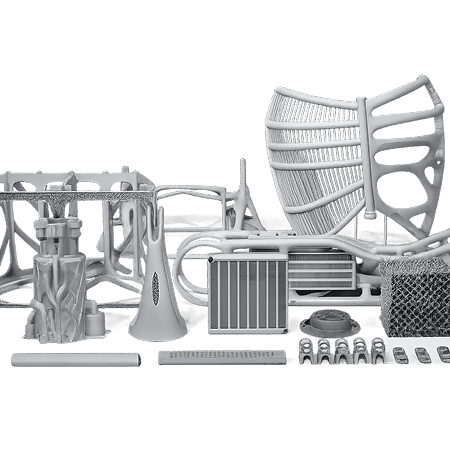

3D Printing Processes

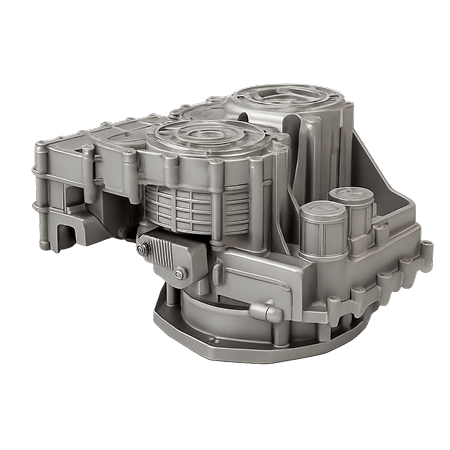

SLM (Selective Laser Melting)

SLM (Metal 3D Printing) prints fully dense metal parts directly from CAD data. Achieves complex structures impossible with traditional machining. Best for aerospace, medical, high-strength lightweight parts.

Aluminum (AlSi10Mg) | Titanium (Ti6Al4V) | Stainless Steel (316L / 17-4PH)

SLS (Selective Laser Sintering)

SLS produces durable, functional nylon parts without support structures. Offers great design freedom for complex geometries and moving assemblies.

Nylon | Glass-Filled Nylon | Carbon-Filled Nylon | TPU

FDM (Fused Deposition Modeling)

The most cost-effective solution for rapid prototyping and simple concept models.

PLA | ABS | PETG | ASA | TPU | Nylon

SLA (Stereolithography)

SLA delivers the smoothest surface finish and highest detail resolution. Perfect for master patterns, clear parts, and cosmetic prototypes.

Photosensitive Resin (ABS-like)

Learn About 3D Printing Materials

Resin (Clear)

Optimized for solid-state SLA platforms. Delivers exceptional clarity and high-precision prints with minimal post-processing. Requires less finishing and simplifies post-curing for faster turnaround.

Resin (White)

This medium-viscosity SLA resin allows easy re-coating and cleaning. It prints strong, dimensionally stable parts in humid conditions with minimal finishing. It cures fast, resists yellowing, shrinks less, and supports high-quality vacuum casting. The white finish is clean, and the material is highly machinable.

Resin (Black)

This ABS-like SLA resin offers strong, stable performance in humid conditions with a long in-machine shelf life. It prints tough, accurate parts that need minimal finishing and fast post-curing. The material is screwable, temperature-resistant, and ideal for vacuum casting. Its color closely matches ABS plastic and delivers great value for cost.

Resin (Translucent)

This translucent SLA resin offers high detail and smooth finish with moderate strength. Ideal for detailed prototypes needing clarity and light transmission. Performs well at room temperature; heat resistance improves with post-curing. Suitable for applications focusing on aesthetics, translucency, and dimensional stability.

ABS (black)

This ABS-like resin delivers strong mechanical performance and good heat resistance, ideal for durable, functional parts. It offers stability under moderate loads and good impact resistance. The black color closely matches traditional ABS, providing a professional finish for prototypes and end-use parts.

Nylon (PA12)

Nylon PA12 is a versatile, high-precision material offering good value. It is flexible enough for thin springs and strong for thick functional parts. Available in various colors, its surface can be polished and dyed. Printed via industrial-grade Selective Laser Sintering (SLS), it absorbs less water than PA6 but is slightly less strong.

Nylon (PA11)

Nylon PA11 is a bio-based material known for its exceptional toughness. It offers high ductility and impact resistance, making it suitable for a wide range of applications. Its skin-safe properties allow for the production of custom medical devices, including orthopedic parts.

Nylon (PA6)

Nylon PA6 is a strong and durable unfilled material commonly used in 3D printing. It offers good mechanical properties and flexibility but requires proper drying before printing due to its high moisture absorption. Ideal for functional parts needing toughness and wear resistance.

PLA Plastic (White)

This is a biodegradable thermoplastic widely used in 3D printing. It offers good tensile strength, dimensional accuracy, and ease of printing but has limited heat resistance and low elongation. Suitable for prototyping and decorative parts.

PLA Plastic (Red)

PLA Plastic Red is a widely used colored PLA for 3D printing, offering mechanical and thermal properties close to standard PLA. It provides good strength and dimensional accuracy with moderate flexibility. Pigments may cause slight variations in density and elongation but generally fall within typical PLA ranges.

PLA Plastic (Black)

PLA Plastic Black typically offers slightly higher rigidity and improved UV resistance due to carbon black pigments. It provides good tensile strength and dimensional accuracy, though its flexibility and elongation may be marginally lower compared to unpigmented PLA. Overall, it remains a reliable choice for standard 3D printing applications.

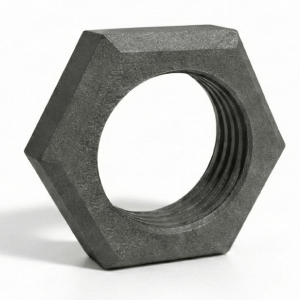

Stainless Steel 17-4 PH

17-4 PH Stainless Steel is a high-strength, corrosion-resistant alloy commonly used in aerospace and industrial fields. Its ability to be heat-treated allows for customized mechanical properties, offering excellent hardness, durability, and wear resistance for demanding applications.

Stainless Steel 316L

316L Stainless Steel is a durable alloy recognized for its excellent corrosion resistance and mechanical strength. Ideal for a wide variety of uses—from industrial parts to decorative items—it provides a dependable option for applications requiring both toughness and a polished appearance.

Stainless Steel Inconel 718

Inconel 718 is a precipitation-hardenable nickel-chromium alloy renowned for its exceptional mechanical strength, corrosion resistance, and thermal stability across a wide temperature range. Engineered for demanding environments, it maintains structural integrity in high-stress and high-temperature conditions, making it ideal for aerospace, power generation, and chemical processing applications.

Aluminium AlSi10Mg

AlSi10Mg is a lightweight aluminum alloy offering a strong balance of mechanical strength, thermal performance, and corrosion resistance. Commonly used in aerospace, automotive, and tooling applications, it is ideal for parts requiring low weight and good dimensional stability.

Aluminum Alloy AI 6061

Aluminum 6061 is a heat-treatable alloy known for its balance of strength, corrosion resistance, and lightweight properties. In 3D printing, it’s ideal for functional parts requiring moderate strength and good post-processing performance, especially after heat treatment.