In the world of precision manufacturing, CNC machining and metal 3D printing are two powerhouse technologies. They take fundamentally different approaches—one subtracts material, the other adds it. Both have unique advantages, limitations, and ideal use cases. If you’re deciding between the two, it’s critical to understand how they stack up in terms of performance, cost, and applications.

Core Principles

CNC Machining – Subtractive Manufacturing

CNC machining works by removing material from a solid metal block using processes like milling, turning, and drilling. Guided by computer-generated toolpaths, CNC delivers high accuracy and consistency but is limited to geometries that cutting tools can reach.

Metal 3D Printing – Additive Manufacturing

Metal 3D printing builds parts layer by layer from metal powders or wires, using technologies such as Selective Laser Melting (SLM) and Electron Beam Melting (EBM). This approach unlocks unprecedented design freedom, enabling internal channels, lattice structures, and topology-optimized shapes.

| Feature | CNC Machining | Metal 3D Printing |

| Process | Removes material | Adds material layer by layer |

| Design Freedom | Limited by tool access | Complex geometries possible |

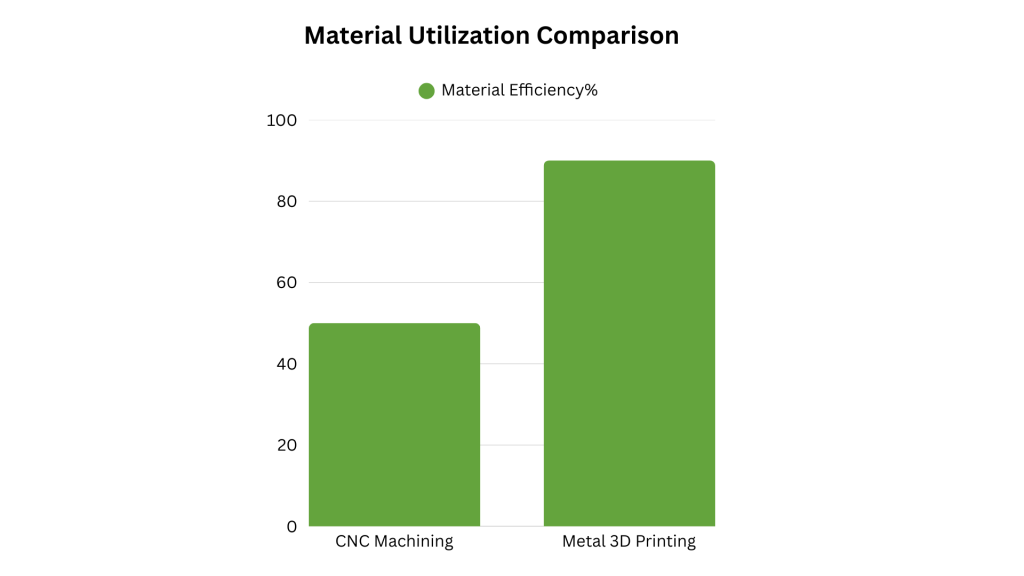

| Waste | High (metal scrap) | Low (only adds needed material) |

| Accuracy/Finish | Excellent as-built | Requires post-processing |

Performance and Capability

Geometric Complexity:

- CNC: Best for simple to moderately complex parts; multi-axis machines add flexibility but struggle with extreme complexity.

- 3D Printing: Excels at producing intricate geometries, lightweight lattice structures, and customized parts.

Material Utilization:

Accuracy and Finish:

- CNC: Delivers high accuracy and excellent surface finish straight off the machine.

- 3D Printing: Often requires post-processing (heat treatment, polishing, machining) to meet dimensional and surface standards.

Cost and Efficiency

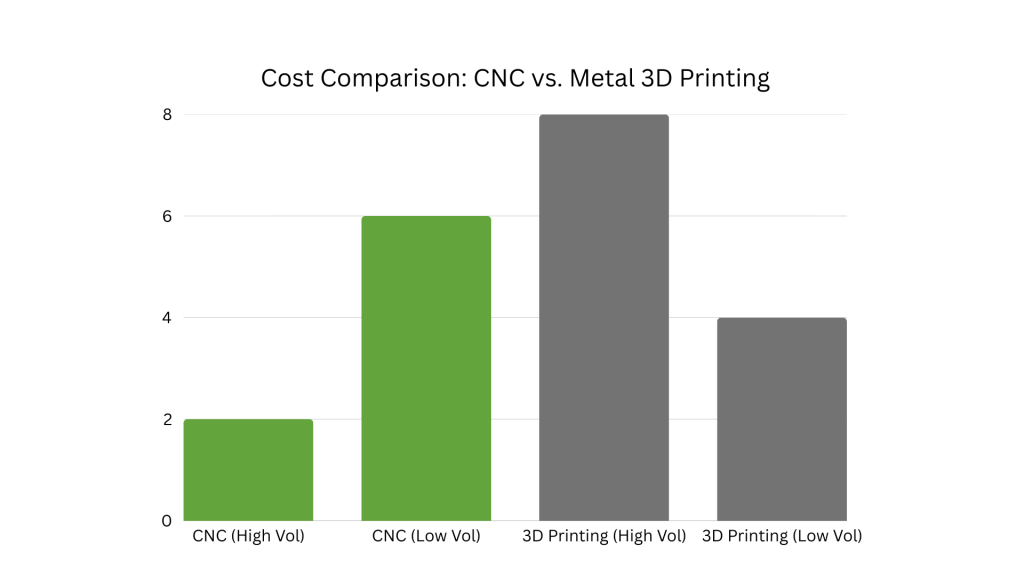

Investment and Unit Cost:

- CNC: Lower upfront equipment costs, economical for high-volume production.

- 3D Printing: Higher initial investment, but cost-effective for low-volume or highly complex parts due to no tooling requirements.

Cost Comparison:

Lead Time:

- CNC Machining: Setup and tooling preparation can extend production timelines, making iteration slower. Lead time varies with the size and complexity of the part, typically ranging from 6 to 12 days including both setup and machining.

- Metal 3D Printing: With a direct-from-digital workflow, no molds or fixtures are required. This enables faster prototyping and iteration. The average lead time is around 5 days, though it can vary depending on the part’s size and geometry.

Typical Applications:

- CNC Machining: Automotive components, molds, high-precision assemblies.

- 3D Printing: Aerospace structures, medical implants, conformal cooling tools, rapid prototyping

Conclusion

Both CNC machining and metal 3D printing bring unique strengths to the table:

CNC is unmatched in accuracy, surface finish, and cost-effectiveness for high-volume production.

Metal 3D printing shines when design freedom, light-weighting, and rapid iteration are top priorities.

The future isn’t about choosing one over the other—it’s about leveraging both strategically. By understanding their differences, businesses can align the right process with their design complexity, cost structure, and production goals.