Your step-by-step guide to how Hyperlab3D turns your 3D model into a finished part.

Introduction

At Hyperlab3D, we make it fast and effortless to turn your 3D model into reality. Whether you’re prototyping a new idea, producing functional parts, or testing a design before mass production—our digital manufacturing system simplifies everything. In this guide, we’ll walk you through how the Hyperlab3D order process works—from uploading your model to receiving the final parts at your door. No confusion, no delays, just smooth and transparent manufacturing.

1. Upload Your 3D Model

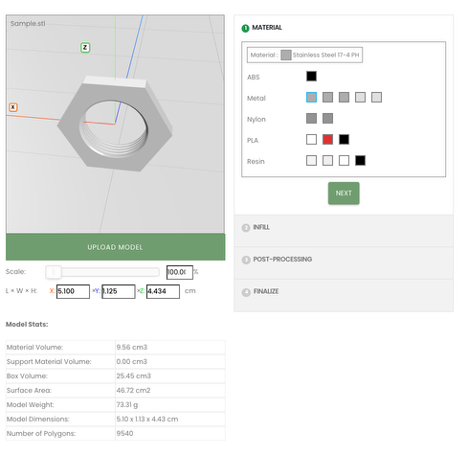

Getting started takes just a few clicks. Simply drag and drop your 3D file onto our upload page, or click “Upload File” to browse your computer. We currently support STL, STEP, and OBJ formats. Once uploaded, our system automatically analyzes your file—checking dimensions, volume, and printability. You’ll see a quick preview of your model, along with a notice if any adjustments are needed. Need to upload multiple parts? No problem. You can upload several files in one order and receive a combined quote. If your file is too large or requires a manual review, just send it to [email protected], and our engineers will handle it for you.

2. Get an Instant Quote

Real-time pricing: Upload → choose material → (for FDM prints, set infill/weight) → pick finishing → see price & lead time instantly. Our pricing is fully transparent — no hidden setup fees or surprise charges. If your project requires special finishing, tight tolerances, or custom materials, click “Request Manual Quote” to get a tailored estimate directly from our engineering team.

3. Choose the Right Material

Each project is unique, and material choice matters. You can easily compare different materials to see how they affect strength, finish, and cost. Common options include:

– SLA Resin: high detail, smooth surface, ideal for visual prototypes

– Nylon (SLS): strong and heat-resistant, perfect for functional parts

– Metal (SLM): stainless steel, aluminum, or titanium for high-performance applications

– CNC Machining: solid metals with precision tolerances for production-level accuracy.

If you’re unsure which to select, visit our Material Guide or contact our engineers for recommendations.

4. Place and Pay for Your Order

Once you’re happy with your quote, click “Add to Cart” and review your order summary. You’ll see all key details—total cost, material, lead time, and shipping estimate—clearly listed before you pay. Hyperlab3D accepts credit cards, PayPal, and bank transfers. After payment, you’ll automatically receive an order confirmation email with your order number and estimated delivery date. Business clients can also request invoices or use their company FedEx account for shipping. Need your parts faster? Just leave a note for expedited production in the comment box before checkout.

5. We Print, Polish, and Inspect

Production time depends on the chosen process and material. Here’s a general overview of what to expect:

– 3D Printing – Plastic (Nylon, Resin, ABS, etc.): typically 2–3 business days

– 3D Printing – Metal (e.g., Stainless Steel, Aluminum, Titanium): usually 5–7 business days

– CNC Machining: generally 7–10 business days

Post-processing time varies depending on the finish and part complexity:

– Sandblasting: +1–2 business days

– Standard Polishing: +3–5 business days

– Mirror Polishing: +5–7 business days

These timelines represent average production speeds under normal workloads. We’ll always notify you if additional time is needed for special surface finishing or highly detailed parts. Before shipping, every part goes through our quality control process:

– Dimensional tolerance check

– Visual inspection

– Surface quality verification

– Secure packaging with protection foam and labels

We don’t ship anything that we wouldn’t proudly use ourselves.

6. Shipping & Tracking

Once your parts pass our quality inspection, we carefully pack them and ship directly to your U.S. address using UPS or FedEx. You’ll receive an email notification as soon as your order has been shipped, including your tracking number and a direct link to follow the shipment in real time. You can also view your order status and tracking number anytime on your Order Page — the system automatically updates once the package leaves our facility. Most orders are delivered within 3–5 business days after shipment. All packages include protective packaging to ensure your parts arrive in perfect condition. Tracking information usually becomes active a few hours after the shipment leaves our warehouse.

7. Receive and Inspect Your Parts

When your package arrives, carefully unbox your parts and check the surface finish, dimensions, and quantity. Each part has been inspected before shipment, but if anything looks off — scratches, deformation, or unexpected surface marks — don’t hesitate to contact us. Our engineering and support teams are always ready to help. Just send us your order number and a few photos, and we’ll review your case right away. If a reprint or adjustment is needed due to production issues, we’ll take care of it promptly at no extra cost. Tip: Keep your packaging and labels for a few days after receiving your parts—it helps us track the shipment if any delivery issue arises.

Conclusion

That’s it—your complete journey from upload to delivery. At Hyperlab3D, we’ve designed our process to be fast, transparent, and reliable, so you can focus on innovation while we take care of the manufacturing. Ready to see your design come to life? Upload your 3D model now and get an instant quote in minutes.