A research team from City University of Hong Kong and MIT just showed how powerful smart design can be when combined with metal 3D printing.

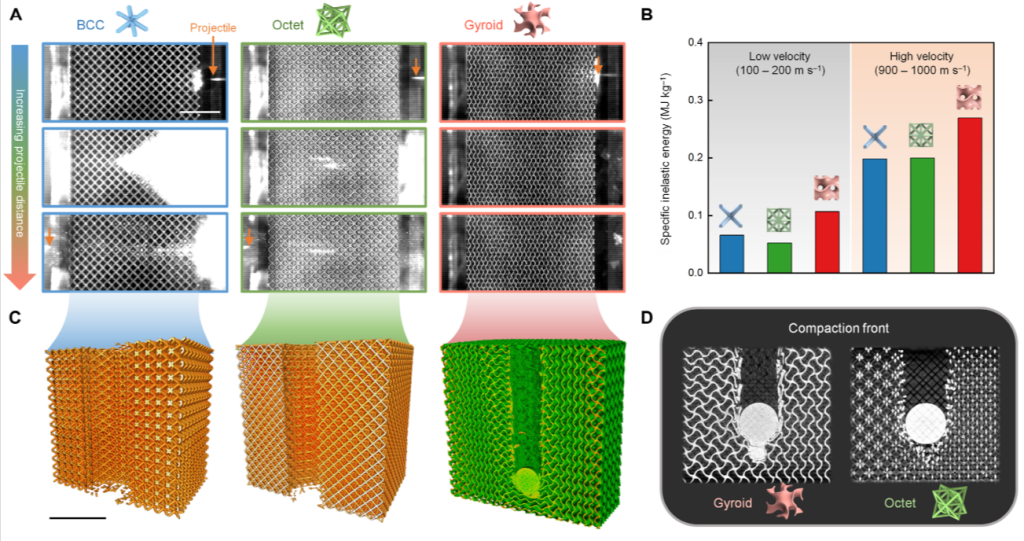

They built a new kind of 3D-printed metal structure that can absorb an insane amount of impact energy. In lab tests, it was able to stop a stainless-steel projectile moving at around 900 m/s—fast enough to punch through most conventional lightweight structures.

That’s a big deal.

The Secret Isn’t Just the Metal

Instead of asking, “How do we make stronger metal?” the researchers asked a better question:

What if the structure itself does the work?

They combined three things:

- a tough CoCrNi medium-entropy alloy

- an advanced gyroid shell geometry

- ultra-precise metal 3D printing

The result? A structure that doesn’t crack or shatter on impact—it gradually deforms and spreads the force, soaking up energy like a shock absorber on steroids.

Shape > Bulk

They tested several internal designs. Traditional truss-style lattices failed once impact speeds passed about 500 m/s.

But the gyroid shell structure kept going—and ultimately stopped the projectile at close to 900 m/s.

Why? Because shell-based designs distribute stress more evenly. Instead of failing at one weak point, the whole structure participates in absorbing energy.

The demonstrated performance could have important implications for a range of applications, including lightweight protective armor, aerospace impact protection, and vehicle safety structures.

Rather than relying on increased thickness or mass, the approach achieves enhanced protection through optimized internal geometry, offering a pathway to lighter and more efficient protective systems.

The research reflects a broader shift in materials science toward architecture-driven design, where performance is defined not only by material composition but also by carefully engineered internal structures.