When engineers evaluate manufacturing options for metal parts, the discussion almost always comes down to two technologies: metal 3D printing and CNC machining. Both are proven, industrial-grade processes capable of producing high-quality, production-ready components.

However, they solve problems in very different ways.

Choosing between the two manufacturing methods is not about picking a “better” technology. It is about understanding what your part needs to achieve, how it will be used, and what constraints actually matter—geometry, performance, volume, lead time, and cost.

This article takes a practical, engineering-focused look at how these two methods compare and how to decide which one makes sense for real-world applications.

Understanding the Two Manufacturing Methods

CNC Machining

CNC machining is a subtractive manufacturing process. A solid block of metal is shaped into a finished part by removing material using cutting tools such as mills, lathes, and drills, all controlled by computer numerical control.

Because CNC machining starts from wrought or forged stock, the resulting parts benefit from well-understood and predictable material properties. Dimensional accuracy is typically excellent, surface finishes are smooth, and repeatability is high. For decades, CNC machining has been the backbone of precision manufacturing across industries ranging from automotive to aerospace and industrial automation.

Metal 3D Printing

Metal 3D printing, also known as metal additive manufacturing, takes the opposite approach. Instead of removing material, it builds parts layer by layer directly from a digital model. One of the most widely used industrial processes is laser powder bed fusion (LPBF), where a laser selectifvely melts fine metal powder to form dense, fully functional metal components.

This layer-by-layer approach fundamentally changes what is possible. Material is placed only where it is needed, allowing engineers to design internal features, complex geometries, and lightweight structures that would be extremely difficult—or impossible—to produce using traditional machining.

| Feature | CNC Machining | Metal 3D Printing |

| Process | Removes material | Adds material layer by layer |

| Design Freedom | Limited by tool access | Complex geometries possible |

| Waste | High (metal scrap) | Low (only adds needed material) |

| Accuracy/Finish | Excellent as-built | Requires post-processing |

Design Freedom: Where the Real Difference Appears

The most significant distinction between CNC machining and metal 3D printing lies in design freedom.

CNC machining is limited by tool access. Cutting tools must physically reach every surface that needs to be machined. As designs become more complex, this limitation becomes increasingly restrictive. Internal cavities, enclosed channels, deep undercuts, and complex internal structures often require multi-axis setups, custom tooling, or design compromises. Each added constraint increases machining time and cost.

Metal 3D printing does not have these access limitations. Internal channels, lattice structures, and topology-optimized geometries can be printed as part of the build itself. This freedom enables designs that are driven by performance requirements rather than manufacturing constraints. For example, internal cooling channels can improve thermal performance, while lattice or shell-based structures can significantly reduce weight without sacrificing strength.

In applications where internal geometry directly impacts function, additive manufacturing often offers a clear advantage.

Cost: Why There Is No Simple Answer

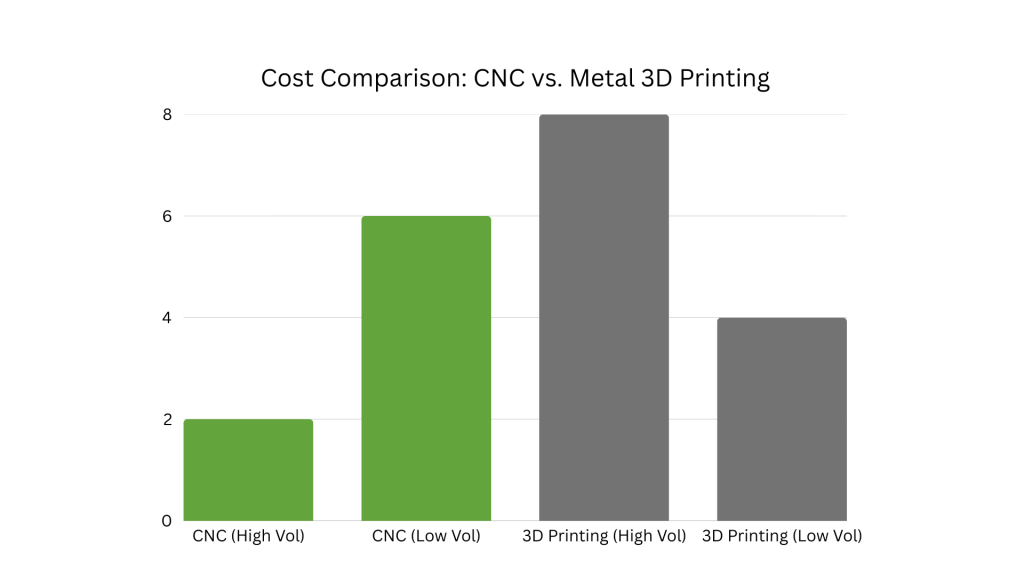

Cost comparisons between the two methods are often misunderstood. There is no universal rule—cost depends heavily on geometry, volume, and system-level considerations.

For simple parts with straightforward geometry, CNC machining is usually more economical. Setup is familiar, cycle times are predictable, and material costs are relatively low. As production volume increases, the cost per part drops quickly, making machining a strong choice for medium- to high-volume production.

Metal 3D printing, on the other hand, becomes cost-effective when complexity increases. Highly complex parts, especially those with internal features, can be printed without a proportional increase in manufacturing cost. In many cases, a single printed part can replace multiple machined components, reducing assembly time, fasteners, and potential failure points. When evaluated at the system level rather than the part level, additive manufacturing can deliver meaningful cost savings.

Materials and Mechanical Performance

Both CNC machining and metal 3D printing support a wide range of engineering metals, including stainless steel, aluminum alloys, tool steels, and titanium.

Machined parts benefit from the consistency of wrought materials, which makes CNC machining a reliable choice for fatigue-critical or load-bearing components with well-defined stress conditions.

Metal 3D printed parts typically require post-processing, such as heat treatment or hot isostatic pressing (HIP), to achieve optimal mechanical performance. When properly processed, printed parts can match—and in some cases exceed—the properties of traditionally manufactured components. More importantly, additive manufacturing allows engineers to design internal structures that outperform solid parts in specific load cases, even when made from the same base material.

Lead Time and Design Iteration

Lead time is another area where the two methods differ significantly.

CNC machining often involves fixture design, toolpath programming, and multiple machining operations. For simple parts, this process can be fast. As complexity increases, however, setup time grows and iteration becomes slower.

Metal 3D printing enables much faster design iteration. Changes can be made directly in CAD without retooling, allowing engineers to move quickly from concept to functional prototype. This flexibility makes additive manufacturing particularly valuable during early development stages, design validation, and low-volume production.

Surface Finish and Tolerances

CNC machining generally delivers tighter tolerances and better surface finishes directly off the machine. For parts where precision interfaces or cosmetic surfaces are critical, machining remains the gold standard.

Metal 3D printed parts often require secondary operations, such as machining or surface finishing, to meet tight tolerance requirements. In practice, many production workflows combine both technologies, using this approach for complex geometry and CNC machining for critical surfaces.

Choosing the Right Method

In practical terms, the decision often comes down to this:

CNC machining is usually the better choice when:

- geometry is relatively simple

- production volume is moderate to high

- tight tolerances dominate the design

Metal 3D printing makes sense when:

- internal complexity drives performance

- weight reduction is critical

- part consolidation adds value

- customization or low volume is required

Increasingly, engineers are not choosing one method over the other but combining both.

Hybrid Manufacturing: A Practical Approach

A common hybrid workflow involves 3D printing the complex geometry and then machining functional interfaces and critical surfaces. This approach allows teams to take advantage of additive manufacturing’s design freedom without sacrificing the precision and surface quality of CNC machining.

For many real-world applications, this hybrid strategy delivers the best balance of performance, cost, and manufacturability.

Final Thoughts

Metal 3D printing and CNC machining are not competing technologies. They are complementary tools within a modern manufacturing toolbox.

CNC machining remains unmatched for precision, simplicity, and scalability. Metal 3D printing unlocks new design possibilities that enable lighter, more efficient, and more functional parts.

The key is not choosing the newest technology by default but understanding what your part needs to do and selecting the manufacturing method—or combination of methods—that supports that goal.

At Hyperlab3D, we help engineers evaluate these trade-offs and choose the right manufacturing strategy based on performance, cost, and lead-time requirements.